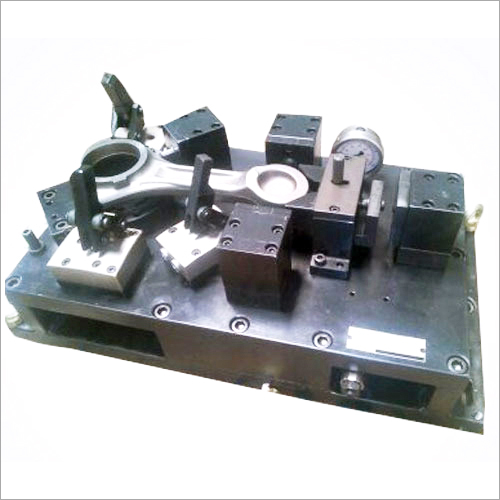

Modular Fixtures

Product Details:

- Working Process CNC Machining & Manual Assembly

- Life Span Up to 5 Years (Depending on Use)

- Die Head Multiple Exchangeable Heads

- Shaping Mode Modular Clamping & Positioning

- Material Alloy Steel / Hardened Steel

- Application Inspection, Machining, Testing, Measurement

- Hardness 58-62 HRC

- Click to View more

X

Modular Fixtures Product Specifications

- Alloy Steel / Hardened Steel

- Modular Clamping & Positioning

- Inspection, Machining, Testing, Measurement

- CNC Machining & Manual Assembly

- Up to 5 Years (Depending on Use)

- Multiple Exchangeable Heads

- 58-62 HRC

- 0.01 mm

Modular Fixtures Trade Information

- All India

Product Description

The Modular Fixtures in combination and coordination with the CAD library for layout and design provide excellent and very important advantages. These are versatile substitute to a single-purpose, dedicated fixture. Made up of a selected kit of interchangeable components, they are conveniently reconfigured for any work holding usage. Plus, these fixtures can easily be dismantled for easy storage when not in use. Over and above, clients can get Modular Fixtures in varied dimensions, grades, finishes, grades and finishes as per their application need.

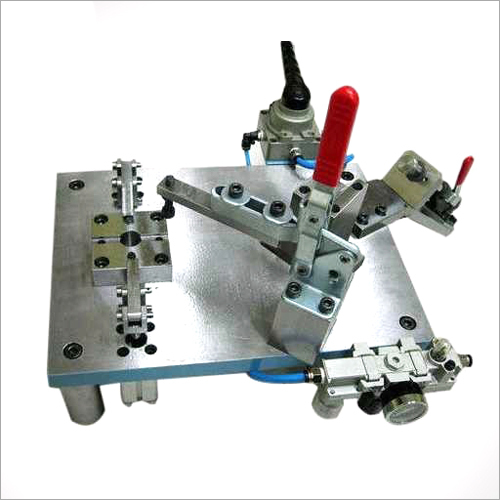

Fully Adjustable Modular Fixtures

Our modular fixtures enable complete flexibility in clamping and positioning, tailored for applications in inspection, machining, testing, and measurement. With exchangeable die heads and quick locking functionality, these units adapt seamlessly to varied operational requirements, optimizing workflow and precision.

Superior Build and Durability

Manufactured from premium-grade alloy and hardened steel, these fixtures are designed to withstand demanding environments. Their anti-rust coating combined with a precision ground finish enhances longevity, supporting a life span of up to five years for consistent, reliable performance in industrial use.

Customization Meets Performance

Every fixture can be customized according to your project drawings, allowing for specialized solutions. CNC machining and manual assembly ensure high accuracy, delivering tight tolerances and modular flexibility suited for unique applications. Choose between table or base plate mounting for optimal integration.

FAQ's of Modular Fixtures:

Q: How are modular fixtures mounted for industrial use?

A: Modular fixtures can be mounted either on tables or base plates, allowing for stable and adaptable integration into different industrial environments. This makes them suitable for a wide range of applications including inspection, machining, and measurement.Q: What is the process behind manufacturing these fixtures?

A: Each fixture is produced using a combination of advanced CNC machining and meticulous manual assembly, ensuring precision and consistent quality. The surface receives a precision ground finish and an anti-rust coating for enhanced corrosion resistance.Q: When should I opt for a custom-designed fixture?

A: Customization is recommended when standard fixtures do not meet your specific sizing or functional requirements. You can provide your drawing and specifications, and the manufacturer will engineer solutions tailored to your application needs.Q: What are the benefits of the quick locking and release clamping system?

A: The quick locking and release system streamlines operations by enabling fast setup and repositioning of workpieces. This improves efficiency, reduces downtime, and supports versatile usage across various tasks.Q: Where can these modular fixtures be used effectively?

A: These fixtures are ideal for quality control labs, CNC machining cells, testing and measurement stations, and assembly lines requiring flexible clamping and precise positioning, with usage spanning inspection, machining, and testing functions.Q: What is the expected lifespan and maintenance of these fixtures?

A: With proper care and maintenance, modular fixtures can last up to five years, depending on the frequency and intensity of use. The anti-rust coating and robust construction minimize wear and extend operational life.Q: Are multiple exchangeable die heads available for these fixtures?

A: Yes, modular fixtures are designed with multiple exchangeable die heads, allowing users to easily adapt the setup to different workpieces or processes without needing entirely new fixtures.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free