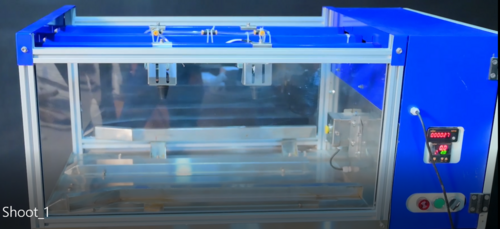

Charged Air Cooling Machine

100 INR/Number

Product Details:

- Product Type Charged Air Cooling Machine

- Material Stainless Steel

- Capacity 500-3000 LPH

- Computerized Yes

- Automatic Grade Automatic

- Control System PLC Controlled

- Processing Type Cooling

- Click to View more

X

Charged Air Cooling Machine Price And Quantity

- 1 Number

- 100 INR/Number

Charged Air Cooling Machine Product Specifications

- Yes

- Silver

- Stainless Steel

- 1500 x 800 x 1400 mm

- Automatic

- 500-3000 LPH

- 450 kg

- 220-380 V

- Charged Air Cooling Machine

- 3-5 HP

- PLC Controlled

- Cooling

Charged Air Cooling Machine Trade Information

- All India

Product Description

The company has brought charged air cooling machine, which is also known as intercooler. This is a device used and installed in internal combustion engines. It also has a purpose to increase the density of air, which enhances engine's performance and efficacy. The air cooling machine helps in the reduction of engine damage risks. This helps in reducing wear caused due to temperature and stress. Charged air cooling machine carries the heat away from engine cylinders. With its installation, the power output could be improved to a great extent.

Efficient Industrial Cooling for Critical Applications

Designed specifically for industrial cooling needs, the Charged Air Cooling Machine delivers precise temperature control to support sensitive processes. Its robust plate/tube heat exchangers maximize the transfer of thermal energy, while automatic PLC control ensures optimal operation and minimal manual intervention.

Advanced Technology Meets Durability

Engineered from high-grade stainless steel, the machine is built for longevity and hygiene in demanding environments. The integration of computerized controls and automatic grade operation means consistent performance, low noise, and easy maintenance. Floor-mounted design ensures stability and simplified installation.

Comprehensive Support and Customization

With on-site support services in India, installation and maintenance are streamlined for users. Flexible cooling capacities, choice of refrigerants, and user-friendly PLC control allow adaptation to diverse industrial requirements, making this unit an ideal choice for manufacturers, wholesalers, and service providers.

FAQ's of Charged Air Cooling Machine:

Q: How does the Charged Air Cooling Machine regulate temperature for industrial applications?

A: The machine uses a hermetic compressor combined with PLC controls to precisely maintain chilling temperatures in the range of 2-8C, ensuring stable thermal conditions critical for various industrial processes.Q: What are the main benefits of using stainless steel as the machine's primary material?

A: Stainless steel offers high durability, resistance to corrosion, and ease of cleaning, making the cooling machine suitable for rigorous, hygienic industrial environments and extending the equipment's operational life.Q: When is on-site support available for installation and maintenance?

A: On-site support is provided by the manufacturer or supplier in India, typically coordinated at the time of installation and throughout the product's operational lifecycle for ongoing maintenance needs.Q: Where can this Charged Air Cooling Machine be installed?

A: Thanks to its floor-mounted design, the machine can be securely set up in industrial plant locations where stability, accessibility for maintenance, and proximity to required utilities are key considerations.Q: What is the process for automated cooling in this system?

A: The system processes water at flow rates between 0.2 and 1.2 m3/hr. PLC automation monitors and controls chilling temperature, water flow, and compressor activity to optimize cooling performance and energy efficiency.Q: How is noise managed within this cooling machine?

A: The design ensures low noise operation under 72 dB, making it appropriate for sites focused on maintaining a quieter workplace without compromising cooling capacity or efficiency.Q: What advantages does computerized, PLC-based control offer for daily operation?

A: Computerized PLC control enables precise adjustments to cooling parameters, real-time monitoring, automatic fault detection, and reduced manual intervention, increasing reliability and process consistency.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email